How to install a steel plate retaining wall: 4 Proven Steps

Transform Your Landscape with a Durable Steel Retaining Wall

Learning how to install a steel plate retaining wall is becoming increasingly popular for homeowners seeking a powerful blend of modern aesthetics and incredible structural strength. In an era where landscape design favors clean lines, industrial textures, and long-lasting materials, steel has emerged as a premier choice. It offers superior durability against the immense forces of soil pressure and erosion, providing a sleek, minimalist look that traditional materials like wood or bulky concrete blocks simply can’t match. For properties in Essex County, particularly those dealing with challenging slopes, soil erosion, or a desire for a contemporary finish, a steel wall is a long-lasting, low-maintenance, and visually striking solution.

Quick Answer: Steel Plate Retaining Wall Installation Steps

- Plan and Design – Meticulously assess your site’s soil and slope, check all local building codes and permit requirements, and call 811 to locate underground utilities before any digging.

- Excavate – Dig a trench for the foundation that is deep enough to extend below the local frost line and wide enough for concrete footings.

- Install Foundation – Create a compacted gravel base for drainage, then set vertical steel posts in reinforced concrete footings, ensuring they are perfectly plumb and aligned.

- Attach Steel Plates – Bolt or slide the steel panels onto the posts, working from the bottom up and keeping each course perfectly level.

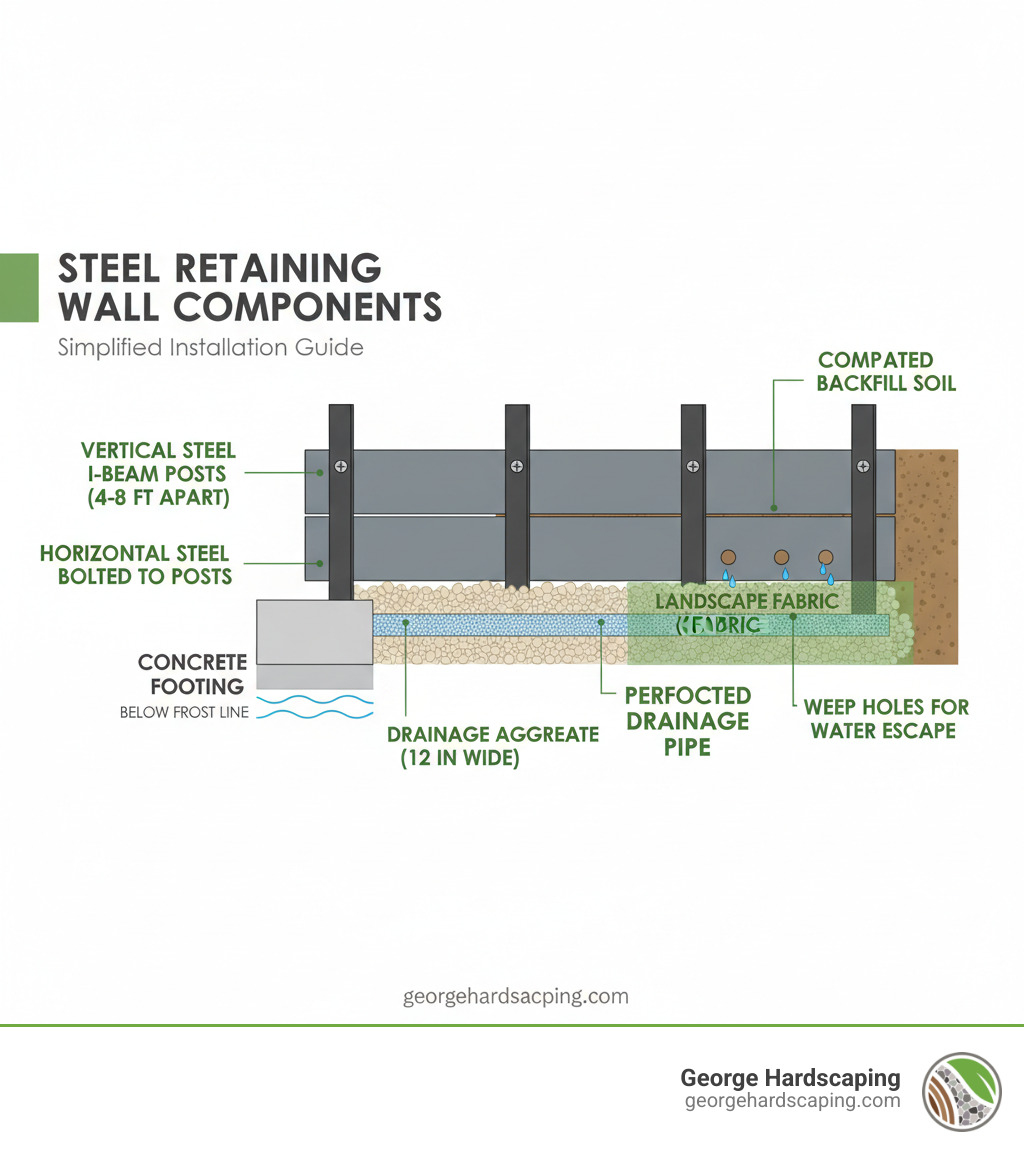

- Add Comprehensive Drainage – Install a perforated pipe at the base, backfill with a deep column of clean drainage gravel, and wrap the gravel in landscape fabric to prevent clogging.

- Backfill and Finish – Fill the remaining space behind the wall with soil in thin, compacted layers (lifts) and grade the final surface to direct water away from the structure.

With a typical lifespan of 50 years or more, steel retaining walls represent a smart, long-term investment in your property’s stability and value. Their remarkably thin profile maximizes usable yard space—a significant advantage for smaller or terraced lots—while providing immense strength capable of holding back tons of earth. This comprehensive guide will walk you through the entire process, from initial planning and material selection to the final landscaping touches, ensuring your project is not only functional and safe but also a stunning architectural feature.

Why Choose a Steel Plate Retaining Wall?

When considering retaining wall materials, steel stands out for its unparalleled combination of raw strength, sophisticated modern aesthetics, and impressive longevity. While wood and concrete have their places, steel often emerges as the superior choice for projects demanding high performance and lasting style. Let’s explore the specific advantages that make it a compelling option.

Unmatched Strength and Durability: Steel is engineered to handle immense hydrostatic and lateral pressure from soil and water, especially on steep slopes or in areas with expansive clay soils. Unlike wood that rots and weakens over time or concrete that can crack under pressure or from settlement, steel holds its form and strength. This structural integrity makes it the ideal material for managing significant grade changes and ensuring long-term stability where other materials might fail.

Exceptional Weather Resistance and Longevity: Steel excels in harsh climates, including the freeze-thaw cycles common in Essex County. While wood is highly susceptible to rot, insect infestation, and warping, and concrete can spall or crack from moisture penetration, specific types of steel are virtually immune to these issues.

- Galvanized Steel: This is carbon steel that has been hot-dipped in a bath of molten zinc. The zinc forms a bonded, sacrificial coating that protects the steel from rust and corrosion. This process ensures the wall remains structurally sound for decades with almost no maintenance.

- Corten Steel: Often called “weathering steel,” Corten is a steel alloy designed to develop a stable, rust-like patina when exposed to the elements. This outer layer of corrosion is not a defect; it’s a protective shield that regenerates over time, completely eliminating the need for painting or sealing. Its deep, earthy tones are highly sought after in landscape architecture.

- Stainless Steel: As the premium option, stainless steel contains chromium, which creates a passive, corrosion-resistant film on its surface. It offers maximum protection against rust and is the best choice for harsh environments like coastal areas with salt spray, though it comes at a higher cost.

This inherent durability means steel walls require very little maintenance and can easily last 50 to 100 years—two to five times longer than even the best pressure-treated wood walls.

Design Flexibility and Modern Aesthetic: Steel provides the clean lines, sharp angles, and industrial-chic look that are hallmarks of contemporary landscape design. The warm, evolving tones of Corten steel can also beautifully complement rustic or naturalistic settings. A key advantage is steel’s strength-to-thickness ratio. Because it is so strong, the plates can be much thinner than concrete blocks or poured concrete walls. This results in a space-saving, low-profile design that maximizes usable yard space—a major benefit for smaller properties or terraced gardens.

Here’s a more detailed comparison of how steel stacks up against the alternatives:

| Feature | Steel Retaining Wall | Wood Retaining Wall | Concrete Retaining Wall |

|---|---|---|---|

| Durability | Excellent; resists immense pressure, rot, pests, and weathering (especially galvanized/Corten). | Fair; susceptible to rot, pests, and warping. Lifespan is significantly shorter. | Good; strong but can crack from major freeze-thaw cycles or improper footing/drainage. |

| Maintenance | Very Low; minimal to no upkeep required for galvanized or Corten steel. | High; requires regular cleaning, sealing/staining to postpone inevitable rot and insect damage. | Moderate; may require occasional power washing, sealing, or crack repair. |

| Aesthetics | Modern, sleek, industrial-chic. Corten develops an attractive, protective rust patina. | Natural, rustic. Weathers and grays over time, can look dated or worn quickly. | Versatile; can be decorative with block faces or smooth with poured concrete, but often looks utilitarian. |

| Lifespan | 50-100+ years with proper installation and materials. | 10-20 years for pressure-treated wood; less for untreated. | 30-50 years, highly dependent on climate, installation quality, and drainage. |

| Strength | Extremely high; can handle very heavy loads and tall walls without buckling. | Moderate; generally unsuitable for walls over 4 feet or those supporting heavy loads like driveways. | High; excellent for load-bearing, but requires significant mass (thickness) to function as a gravity wall. |

| Profile | Thin, space-saving design that maximizes usable yard area. | Moderate to thick, depending on the size of the timbers used. | Thick and often bulky, especially for gravity walls, consuming significant yard space. |

| Installation Complexity | High; requires precision, heavy equipment, and often welding or specialized fastening. | Moderate; can be a DIY project for shorter walls, but requires significant labor. | High for poured walls; moderate for segmental blocks, but requires precise base preparation. |

For homeowners in Essex County, choosing steel for your Landscape Retaining Walls is a strategic investment in a practical, stylish, and exceptionally long-lasting solution that enhances property value for generations.

Planning and Designing Your Steel Retaining Wall

Proper planning is the most critical phase of learning how to install a steel plate retaining wall. A successful, long-lasting project is built on a foundation of thorough site analysis, adherence to local regulations, and informed material choices. Rushing this stage is the single biggest predictor of future problems.

Comprehensive Site Assessment:

Start with a detailed analysis of your property. What is your soil composition? Sandy soil drains well but offers less structural support, while heavy clay soil retains water, which can dramatically increase hydrostatic pressure on the wall. You can perform a simple percolation test by digging a hole, filling it with water, and timing how long it takes to drain to gauge your soil’s drainage capacity.

Observe the slope of your land. A steep grade exerts exponentially more force and will require a more robust, likely engineered, design. Use stakes and a string level to accurately measure the change in elevation. Also, carefully note where water flows during heavy rain, as this will be the blueprint for your drainage plan. A properly designed drainage system is the number one defense against wall failure.

Regulations, Permits, and Safety:

Before a single shovel of dirt is moved, you must address these critical legal and safety requirements:

- Call 811 (Dig Safe): This free, mandatory service locates and marks all underground utility lines (gas, electric, water, communications). Digging without this clearance is illegal, extremely dangerous, and can lead to life-threatening situations and massive liability. Make the call several days before you plan to excavate.

- Check Local Building Codes: Every municipality in Essex County, from Andover to Salisbury, has specific regulations for retaining walls. Contact your local building department to ask about permit requirements, height limitations (often 3-4 feet is the maximum before an engineer is required), and property line setbacks. You can find general guidance from sources like the International Code Council (ICC), but your local municipal codes always take precedence.

- Hire a Structural Engineer: This is not optional for most walls. For any retaining wall over 3-4 feet tall, or any wall supporting a critical load (like a driveway, pool, or another structure), jurisdictions legally require a design stamped by a licensed structural engineer. They will perform calculations for soil pressure, surcharge loads, and overturning forces to design a safe, stable wall that complies with all building codes. This is a necessary investment to prevent catastrophic failure and ensure legal compliance.

Choosing the Right Steel and Specifications:

As discussed, your choice of steel impacts longevity, cost, and aesthetics. Corten steel offers a natural, protective rust patina ideal for modern and rustic designs, though it can cause staining on concrete or pavers below during its initial 1-2 year weathering period. Galvanized steel provides long-term, maintenance-free corrosion protection with a more industrial, silvery-gray finish. For the ultimate in durability, especially in coastal areas with salt spray, stainless steel is the premier choice, though it comes at a premium price.

Beyond the type, you must consider the thickness (gauge) of the steel. A taller wall or one holding back heavy, wet clay soil will require thicker steel plates and heavier I-beam posts than a short, decorative wall in sandy soil. An engineer will specify the required thickness (e.g., 1/4 inch, 3/8 inch) and post size/spacing in their plans. Attempting to guess these specifications is a recipe for failure.

A professional can help integrate your wall into a cohesive vision. Our Hardscape Design Services ensure your retaining wall works in harmony with patios, walkways, and plantings for a beautiful, functional, and unified landscape.

How to Install a Steel Plate Retaining Wall: A Step-by-Step Guide

With your engineered plans approved and materials on site, it’s time for the physical installation. This process demands precision, heavy lifting, and an unwavering commitment to following the design specifications. Here’s a detailed breakdown of how to install a steel plate retaining wall correctly.

Essential Tools and Materials

Gathering every single item beforehand is crucial for a smooth, safe, and efficient project. Sourcing steel may involve contacting local steel fabricators or specialized online suppliers.

- Safety Gear: ANSI-rated safety glasses, heavy-duty leather gloves, steel-toed boots, hearing protection (for grinders/compactors).

- Excavation & Earth-Moving Tools: Round-point shovel, pickaxe, trenching spade, gas-powered auger or post-hole digger, heavy-duty wheelbarrow, and potentially a mini-excavator for larger projects.

- Layout & Leveling Tools: 25-foot tape measure, 4-foot level, string line with line level, marking paint or stakes, and a laser level for establishing accurate grades over long distances.

- Compaction & Concrete Tools: Hand tamper for tight spaces, plate compactor for trenches and backfill, portable concrete mixer or mixing tub, shovel, and trowel.

- Cutting & Fastening Tools: Angle grinder with metal cutting and grinding discs, magnetic drill press for precise holes, impact wrench with sockets appropriately sized for your bolts, and a torque wrench to ensure proper fastener tension.

- Primary Materials: Steel plates (Corten, galvanized, or as specified) and vertical steel I-beam or H-beam posts of the specified size and weight.

- Foundation & Drainage Materials: Bagged ready-mix concrete (ensure it’s rated for at least 3000 PSI), 3/4-inch clean crushed gravel (no fines), 4-inch (100mm) perforated drain pipe with sock, and heavy-duty non-woven geotextile landscape fabric.

- Fasteners: A325 hot-dip galvanized structural bolts, nuts, and washers.

If sourcing these specialized materials and heavy equipment feels daunting, our Retaining Wall Installation Services can manage the entire procurement and construction process for you.

Step 1: Site Preparation and Excavation

This step lays the literal groundwork for your wall’s stability. Accuracy here prevents major problems later.

- Clear the Area: Remove all grass, plants, rocks, and debris from the wall’s location and a wide working area around it.

- Mark the Layout: Using your engineered plans, drive stakes and run a tight string line to mark the exact face of the wall. Use marking paint to outline the trench area.

- Call 811 (Mandatory): If you haven’t already, stop and call 811 to have all underground utility lines professionally marked. Do not dig until this is complete.

- Excavate the Trench: Dig a trench that is deep enough to go below your local frost line (in Essex County, this is typically 48 inches) and wide enough to accommodate the post footings (often 18-24 inches). A critical rule of thumb is that at least one-third of the total post length should be buried.

- Level and Compact: Ensure the bottom of the trench is perfectly level along its entire length. Use a hand tamper or plate compactor to compact the soil at the base until it is firm and unyielding.

Proper excavation is the cornerstone of professional Retaining Wall Construction.

Step 2: How to Install a Steel Plate Retaining Wall Foundation

A steel wall is only as strong as its foundation. Do not cut corners here; this is what prevents leaning and failure.

- Add Gravel Base: Place and compact a 4-6 inch layer of 3/4-inch clean gravel at the bottom of the trench. This creates a stable, load-bearing surface and improves drainage beneath the footings.

- Set the Posts: Place the vertical steel I-beam or H-beam posts into the trench at the precise intervals specified in your plans (e.g., every 4-6 feet). A common engineering principle is that the post depth below ground should equal the wall height above ground (a 1:1 ratio) to provide adequate leverage against soil pressure.

- Plumb and Brace: Use a 4-foot level on two adjacent faces of each post to ensure it is perfectly plumb (vertical). Run a string line across the front of the posts to ensure they are perfectly aligned. Brace them securely with 2x4s and stakes so they cannot move during the concrete pour.

- Pour Concrete Footings: Mix and pour high-strength (3000+ PSI) concrete into the trench around each post, filling to the specified depth. Vibrate the concrete with a rod or by tapping the posts to remove air pockets. Allow the concrete to cure undisturbed for at least 48-72 hours (or as directed by the manufacturer) before applying any load.

This process is fundamental to creating Structural Landscaping that is built to last a lifetime.

Step 3: How to Install a Steel Plate Retaining Wall Assembly and Drainage

Now the wall takes shape. Drainage is not an afterthought; it is integrated at this stage and is absolutely vital for the wall’s longevity.

- Attach Steel Plates: Starting from the bottom, bolt or slide the steel plates into position against the posts. Use a level to ensure each course is perfectly horizontal. Use hot-dip galvanized structural bolts and tighten them in a star pattern to ensure even pressure. Do not fully torque until all plates are in place.

- Install Drain Pipe: Lay a 4-inch perforated drain pipe (with a fabric sock to prevent clogging) along the base of the wall on the soil side. Ensure it has a slight, continuous slope (at least 1/8 inch per foot) to a daylight exit point, directing water away from the wall.

- Add Drainage Gravel: Backfill directly behind the wall with a 12- to 18-inch-wide column of clean 3/4-inch gravel. This column should extend from the footing to within 6 inches of the final grade, surrounding the drain pipe completely. This creates a highly permeable channel for water to flow down to the pipe, relieving hydrostatic pressure.

- Install Geotextile Fabric: Drape a layer of non-woven geotextile landscape fabric between the gravel drainage zone and the native soil. This acts as a critical filter, preventing soil and silt from migrating into and clogging the gravel, which would render the drainage system useless.

- Incorporate Weep Holes: As specified in your design, create weep holes. These can be small gaps left between plates in the lowest course or, more effectively, 3/4-inch PVC pipes installed through the bottom plate to provide an additional outlet for any trapped water.

There is no such thing as too much drainage. For a professionally designed and installed solution, consider our Retaining Wall Drainage System services. A great visual guide can be found in this video: EPIC DIY Backyard Steel Retaining Walls & Stairs – Start to Finish.

Step 4: Backfilling and Finishing Touches

The final step is to carefully secure the wall by backfilling and then integrate it into your landscape.

- Backfill in Lifts: Add soil behind the fabric-wrapped gravel drainage layer in thin, even layers of 6-8 inches at a time (these are called “lifts”). Do not simply dump all the soil in at once.

- Compact Each Layer: After adding each lift, use a hand tamper or plate compactor to thoroughly compact the soil. This process is tedious but absolutely essential to prevent future soil settlement, which can put immense downward pressure on the wall and cause surrounding areas to sink.

- Final Grade: Add the final layer of topsoil and carefully grade the surface so it slopes gently away from the top of the wall. This ensures that surface water from rain or irrigation is directed away from the structure, not towards it.

- Landscape and Mulch: Finish the area by planting vegetation with non-invasive root systems, adding a layer of mulch to prevent erosion, or incorporating other hardscape features. This helps stabilize the soil and beautifies the completed project.

Our team at George Hardscaping specializes in Hardscape Installation Near Me, ensuring a professional finish that enhances the beauty and functionality of your entire property.

Ensuring Structural Integrity and Longevity

Installing a steel wall is not just about putting up panels; it’s about creating a permanent structural element that will perform flawlessly for decades. This requires an unwavering focus on structural integrity, especially for taller walls or those on challenging sites.

Advanced Reinforcement for Taller Walls

As a retaining wall’s height increases, the lateral earth pressure it must resist increases exponentially. For any wall over 4 feet, standard post-and-panel construction is often insufficient. A structural engineer must design a reinforcement system to anchor the wall securely into the soil mass behind it. Common methods include:

- Tieback Anchors: High-strength steel rods are drilled diagonally through the wall posts deep into the stable soil behind the failure plane. They are then grouted in place and tensioned, actively pulling the wall back and counteracting the outward pressure.

- Deadman Anchors: Large concrete blocks or logs (“deadmen”) are buried deep in the backfill, well behind the wall. Steel rods or cables connect these anchors to the wall posts. The weight of the soil on top of the deadman provides a massive, passive anchor point.

- Geogrid Reinforcement: This is a synthetic grid-like material laid horizontally within the backfill soil as it’s being compacted. The soil interlocks with the grid, creating a unified, reinforced soil mass that has much greater internal strength and acts as a cohesive block, reducing the lateral pressure on the wall itself.

- Helical Anchors: These are essentially giant steel screws that are mechanically drilled deep into the ground until they reach a specified torque in competent soil. They provide an exceptionally strong anchor point, especially useful in poor soil conditions where traditional anchors might not hold. We have extensive experience with Helical Anchors Retaining Wall solutions for the most challenging sites in Essex County.

Crucially, any wall over 3-4 feet tall, on a significant slope, or supporting a load (like a driveway or patio) requires a design by a qualified structural engineer. This is a non-negotiable safety, legal, and insurance requirement.

Common Challenges and Proactive Solutions

- Challenge: Steep Slopes.

- Solution: Instead of one dangerously tall wall, build a series of shorter, terraced walls. This is far more stable, manages water more effectively, and creates usable, level garden beds or patios.

- Challenge: Poor Soil Conditions (Expansive Clay, Loose Sand).

- Solution: The unstable native soil may need to be over-excavated and replaced with compacted structural fill (like dense-grade gravel) to create a solid, non-expansive base for the wall’s foundation.

- Challenge: Corrosion Concerns.

- Solution: The best solution is proactive material selection—use galvanized or Corten steel for built-in, long-term protection. If using mild steel for any reason, it must be meticulously prepared and coated with a high-performance, marine-grade epoxy coating system.

- Challenge: Hydrostatic Pressure.

- Solution: This is the #1 cause of all retaining wall failures. A comprehensive drainage system (perforated pipe, deep gravel backfill, and geotextile fabric) is not an optional upgrade; it is the most essential component for the wall’s longevity. Never skimp on drainage.

If you encounter issues with an existing, failing structure, our Hardscape Repair Near Me team can diagnose the cause and provide professional stabilization and repair solutions.

Long-Term Maintenance Checklist

While steel walls are famously low-maintenance, they are not “no-maintenance.” A few simple annual checks will ensure a long, trouble-free life:

- Inspect Annually: Each spring and fall, and after major storm events, walk the length of the wall.

- Look for Bulging or Leaning: Any deviation from a perfectly straight, plumb line is a red flag. Even slight movement can indicate a serious problem with drainage or footing. If you see any, call a professional immediately.

- Check Weep Holes: Ensure the small drainage holes at the base of the wall are clear of leaves, dirt, and debris so water can escape freely.

- Manage Drainage Outlets: Make sure the exit point of your main drain pipe is clear and not blocked by vegetation or soil buildup.

- Address Surface Rust (if applicable): For Corten steel, the rust is a protective patina—leave it alone. For a painted or coated steel wall, if you see any bubbling paint or rust spots, sand the area down to bare metal, prime, and reapply a high-quality protective coating promptly to prevent it from spreading.

With proper installation and these minimal care steps, major repairs should not be necessary. For more information on potential issues and their costs, see our guide on the Cost of Repairing Retaining Wall.

Cost, ROI, and When to Hire a Professional

Understanding the financial commitment, long-term value, and the line between a feasible DIY project and a necessary professional job is key when planning a steel retaining wall.

Budgeting for Your Steel Retaining Wall

The total cost of a steel retaining wall is highly variable and depends on a detailed breakdown of several factors:

- Material Costs:

- Steel: The price of Corten or galvanized steel plates and I-beams is a primary driver. This is influenced by market steel prices, thickness (gauge), and total weight.

- Concrete & Gravel: The volume of ready-mix concrete and clean drainage gravel needed for footings and backfill.

- Drainage Components: Cost of perforated pipe, geotextile fabric, and fasteners.

- Labor Costs:

- Excavation & Site Prep: This is labor-intensive and may require heavy equipment.

- Installation: The skilled labor for setting posts, placing panels, welding (if required), and fastening.

- Backfilling & Compaction: The meticulous process of backfilling in lifts.

- Equipment Rental: Costs for mini-excavators, plate compactors, concrete mixers, or augers if you are undertaking a DIY project.

- Professional Fees:

- Engineering Fees: A necessary cost for any wall over 3-4 feet, which can range from several hundred to a few thousand dollars.

- Permit Fees: The cost charged by your local municipality to review and approve the plans.

Based on aggregated internet data, residential retaining walls can range from $3,000 to $15,000, with complex, engineered steel walls often exceeding $30,000 or more. (Note: these are general industry estimates and not quotes from George Hardscaping). For an accurate estimate tailored to your specific project, consult our detailed guide on How Much Does a Retaining Wall Cost?

The Powerful Long-Term Value Proposition (ROI)

While the initial cost of a steel wall may be higher than a simple wood wall, it provides an excellent and durable return on investment (ROI). Its 50-100+ year lifespan means you avoid the significant cost and disruption of replacing a rotted wood wall every 10-20 years. The extremely low maintenance requirements of galvanized and Corten steel save you time and money on sealants, stains, and repairs over the decades. Furthermore, a professionally installed steel wall delivers tangible value by:

- Preventing Costly Erosion: It stops soil from washing away and potentially damaging your home’s foundation, patios, or other landscape features.

- Creating Usable Land: It transforms an unusable slope into valuable, flat real estate for gardens, patios, or play areas.

- Boosting Curb Appeal: Its modern, high-end aesthetic directly increases your property’s perceived and actual market value.

DIY vs. Calling in the Pros: A Critical Decision

While this guide explains how to install a steel plate retaining wall, a DIY approach is only suitable for very small, non-critical, decorative walls (under 2-3 feet high on flat ground with no load behind them).

You absolutely must hire a professional when:

- The wall is over 3-4 feet tall.

- The site is on a steep slope or has known poor soil conditions.

- The wall will support a critical load like a driveway, patio, swimming pool, or the foundation of a building.

- The design is complex, involving curves, tiers, or integrated stairs.

- You do not have experience with heavy equipment, structural principles, and local building codes.

The risks of an improperly built retaining wall are enormous, including catastrophic failure that can cause immense property damage and pose a safety hazard. Professionals bring the right equipment, liability insurance, engineering knowledge, and an understanding of local codes to ensure the job is done safely, legally, and correctly the first time. For homeowners in Essex County, hiring an experienced Retaining Walls Contractor provides the peace of mind that your significant investment is built to last for generations.

Frequently Asked Questions about Steel Plate Retaining Walls

Here are concise answers to some of the most common questions we receive from homeowners in Essex County considering a steel retaining wall.

How long do steel retaining walls last?

A properly installed steel retaining wall made from quality materials like hot-dip galvanized or Corten steel can easily last 50 to 100 years, or even longer. Its inherent resistance to rot, pests, and weathering gives it a lifespan that far exceeds wood and often surpasses that of concrete walls, which can be susceptible to cracking from freeze-thaw cycles.

Do I need a permit to build a steel retaining wall?

Almost certainly, yes. Permit requirements vary by town, but virtually every municipality requires a building permit and an engineered design for any retaining wall over 3-4 feet in height. Even shorter walls may require a permit depending on their location (e.g., near a property line) or if they are supporting a load (a “surcharge”) like a driveway or slope. Always check with your local building department before starting any work.

How do you prevent a steel retaining wall from rusting?

Rust prevention starts with smart material selection. Galvanized steel is coated in a thick layer of zinc for sacrificial protection, while Corten steel is specifically designed to form a stable, protective rust patina that prevents deeper corrosion. For any other type of steel, a high-performance, multi-layer marine-grade coating is necessary. Most importantly, a properly installed retaining wall drainage system is the best defense against corrosion, as it keeps constant moisture away from the steel.

How thick should the steel plates be for a retaining wall?

The required thickness of the steel plates depends entirely on the wall’s height, the type of soil, and any additional loads (surcharges). A small, 2-foot decorative wall might use 1/8″ or 3/16″ plate, while a 6-foot engineered wall holding back clay soil might require 3/8″ or 1/2″ plate. This is not a DIY decision. A structural engineer must calculate the forces and specify the appropriate steel thickness and post size in the official plans.

Can you install a steel retaining wall on a curve?

Yes, but it adds significant complexity and cost. Creating a smooth curve requires either using a series of short, straight, segmented panels to approximate the curve, or having the steel plates professionally rolled to the desired radius by a metal fabrication shop. This is an advanced technique that absolutely requires professional design and installation.

What is the difference between I-beams and H-beams for posts?

I-beams and H-beams are structurally similar. The main difference is that H-beams typically have wider, thicker flanges, giving them slightly more strength in multiple directions. For most retaining wall applications where the primary force is perpendicular to the web, either can be used effectively. An engineer will specify the exact type, size, and weight (e.g., W8x24) of the beam required for the project based on their load calculations.

What maintenance does a Corten wall need during its initial weathering?

During the first 1-3 years, the Corten steel’s patina is developing and can produce a rust-colored runoff during rain. This can stain surfaces like concrete patios or light-colored pavers below the wall. While the wall itself needs no maintenance, you may need to protect or plan for cleaning the surfaces below. Some people accelerate the patina process with a mild acid solution, but it’s often best to let it happen naturally.

Conclusion: A Lasting Investment in Strength and Style

This guide has detailed how to install a steel plate retaining wall, showcasing why it has become a premier choice for discerning homeowners. By combining industrial-grade strength, a sleek and modern style, and incredible durability, steel offers a permanent solution that protects your property, creates valuable usable space, and adds significant architectural appeal and financial value to your home.

The key to unlocking a 50+ year lifespan lies in meticulous and correct installation. There are no shortcuts. A solid, deep foundation, a comprehensive and non-negotiable drainage system, and the involvement of a structural engineer for any wall of significant height are the three pillars of a successful project. While a very small, decorative wall can be a rewarding DIY project for the ambitious homeowner, most steel retaining walls—especially those critical for soil retention—demand professional expertise to ensure safety, compliance, and longevity.

Ready to transform your landscape with a stunning and bulletproof steel retaining wall?

The experts at George Hardscaping have years of experience designing and building beautiful, structurally sound retaining walls across the North Shore. We understand the local soil, climate, and building codes, ensuring your project is engineered and constructed to last for generations. Contact us today for a free, no-obligation estimate on your Hardscaping Masonry Services project and invest in a permanent solution for your property!