Large Retaining Wall Construction: Top 10 Steps for Success

Introduction

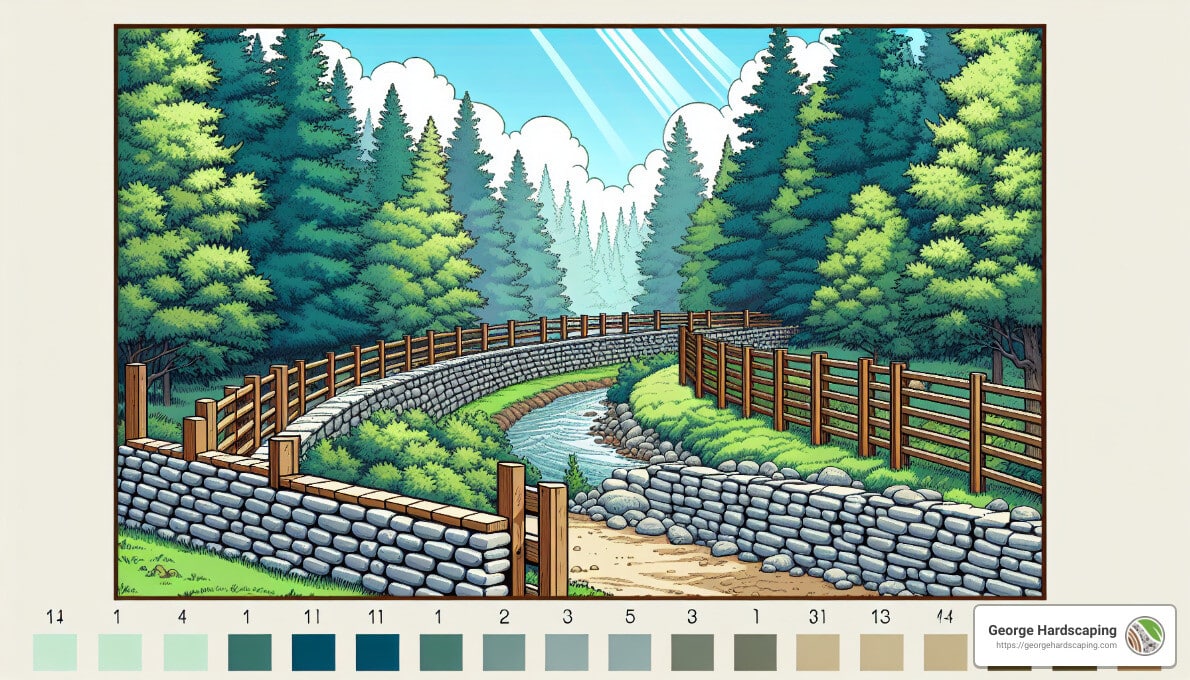

Large retaining wall construction might seem daunting, but it’s essential for managing soil erosion, using sloped land, and creating stunning outdoor spaces. Here’s a quick overview to get you started:

- Begin with Planning: Assess the site and design considerations.

- Choose Quality Materials: Concrete, stone, or blocks.

- Prepare the Site: Excavate, trench, and prepare the base.

- Build with Care: Layer, backfill, and ensure proper drainage.

A retaining wall’s primary purpose is to hold back soil and prevent erosion. It’s a critical component for both safety and aesthetics in landscaping. Without proper planning and execution, retaining walls can fail, leading to expensive repairs and potential hazards.

Safety first: Taller retaining walls require thorough engineering and might need building permits. Always comply with local regulations and consider hiring professionals for walls exceeding 4 feet in height.

When done right, a large retaining wall is both functional and beautiful, turning awkward slopes into usable, stylish garden spaces.

Planning Your Large Retaining Wall Construction

Site Assessment

Before you start digging, a thorough site assessment is crucial. Begin by evaluating the slope, soil type, and drainage conditions of your site. Soil is heavy, especially when wet, and poor soil conditions can lead to wall failure.

Tip: Sandy and gravelly soils drain well and are more stable, while clay soils retain water and can exert more pressure on your wall.

Case Study: Joe Blakeborough from Blakeborough Hardscapes emphasizes the importance of understanding soil conditions to prevent erosion and ensure the longevity of the retaining wall. His team often conducts soil tests to determine the best approach for each project.

Design Considerations

Designing a large retaining wall involves more than just stacking blocks. Here are some key considerations:

- Height: Walls over 4 feet often need a plan from a licensed engineer.

- Materials: Choose between concrete, stone, or blocks depending on aesthetics and functionality. MagnumStone’s hollow core blocks are a great choice for large walls due to their strength and ease of installation.

- Drainage: Proper drainage prevents water buildup behind the wall, which can cause pressure and lead to failure.

Fact: MagnumStone blocks use 40% less concrete than solid block systems, making them a cost-effective and versatile option.

Permits

Don’t forget to check with the authorities. Many communities require permits for large retaining wall construction due to the potential impact on natural water flow and neighboring properties.

Steps to Obtain a Permit:

1. Submit Plans: Provide detailed design plans, including wall height, materials, and drainage solutions.

2. Inspection: Schedule an inspection to ensure your plans meet local regulations.

3. Approval: Once approved, you can proceed with construction.

Pro Tip: Always call DigSafe (811) before you start digging to avoid hitting underground utilities.

By carefully planning your large retaining wall construction, you can ensure a safe, durable, and aesthetically pleasing result.

Next, we’ll dive into Choosing the Right Materials for Large Retaining Walls.

Choosing the Right Materials for Large Retaining Walls

Choosing the right materials is crucial for large retaining wall construction. The right materials ensure durability, stability, and aesthetic appeal. Here’s a breakdown of popular options:

Concrete

Concrete is a popular choice for retaining walls due to its strength and versatility. It can be molded into various shapes and sizes, making it ideal for custom designs. Concrete also withstands harsh weather conditions and requires minimal maintenance.

Benefits:

– Durability: Long-lasting and resistant to weather.

– Versatility: Can be customized for different designs.

– Strength: Handles heavy loads and soil pressure.

Stone

Stone retaining walls offer a natural and timeless look. They are highly durable and blend well with natural landscapes. However, they can be more expensive and labor-intensive to install.

Benefits:

– Aesthetic Appeal: Natural and rustic look.

– Durability: Resistant to weather and erosion.

– Strength: Excellent for holding back large amounts of soil.

Blocks

Blocks are a common material for retaining walls due to their ease of use and cost-effectiveness. They come in various types, including solid and hollow blocks.

Benefits:

– Ease of Installation: Simple to stack and align.

– Cost-Effective: More affordable than stone or custom concrete.

– Versatility: Available in different shapes and sizes.

Magnum Block

Magnum Block is a specialized retaining wall system known for its high strength and advanced design. These blocks are hollow, using 40% less concrete than solid blocks, making them lighter and easier to handle.

Benefits:

– Efficiency: Hollow design reduces concrete use.

– Strength: Engineered for high load-bearing capacity.

– Versatility: Fits various design and application needs.

Case Study: A MagnumStone project showcased the system’s versatility and strength, transforming a steep slope into a usable space with a beautiful retaining wall.

Hwy Blocks

Hwy Blocks are large precast concrete blocks designed for heavy-duty retaining walls. They are ideal for projects requiring significant load-bearing capacity and stability.

Benefits:

– Heavy-Duty: Suitable for large-scale projects.

– Durability: Withstands heavy loads and harsh conditions.

– Ease of Use: Precast design simplifies installation.

When choosing materials for your large retaining wall construction, consider factors like durability, cost, and aesthetic appeal. Each material has its unique benefits, so choose the one that best fits your project’s needs.

Next, we’ll explore Preparing the Site for Construction.

Preparing the Site for Construction

Excavation

Before you start building, you need to prepare the site. Proper excavation is crucial. Begin by marking the area where the wall will go. Use stakes and string to outline the wall’s boundaries.

Next, dig out the soil. The trench should be wide enough for the wall blocks and at least 8 inches of space behind them. It should also be deep enough to bury one full course of blocks plus 6 to 8 inches of base material.

Tip: Use a laser level and a story pole to ensure the trench is even. This helps prevent the wall from tipping during freeze/thaw cycles.

Trenching

Once the excavation is complete, you need to trench the area. The trench should be level and properly sized. Make sure it is wide enough to accommodate the blocks and has extra space for backfill material.

Compact the soil at the trench bottom with a hand tamper or a vibrating plate compactor. This step is often overlooked but is essential. Loose soil can cause the wall to settle, leading to instability.

Base Preparation

A solid base is the foundation of a long-lasting retaining wall. Use crushed stone, not naturally occurring gravel. Crushed stone provides better drainage and requires less compacting. It stays compacted once set.

Joe and Jake, hardscaping pros, recommend crushed stone sized between 1/2 inch and 3/4 inch. This size handles the heaving forces from freeze/thaw cycles effectively. Avoid rounded stones like pea gravel. They don’t form strong interlocking bonds.

Leave the stone no more than 1/2 inch higher than the final height you want. Make a couple of passes with a hand tamper or plate compactor. The stone will be almost 100 percent compacted as soon as it’s laid in the trench.

Pro Tip: Use the same type of crushed stone for backfilling. This eliminates the need for multiple materials and simplifies the process.

By following these steps, you ensure a strong foundation for your large retaining wall construction. Next, we’ll discuss Building the Foundation for a Retaining Wall.

Building the Foundation for a Retaining Wall

Base Material

Choosing the right base material is crucial for a long-lasting retaining wall. Our experts recommend using crushed stone rather than naturally occurring gravel. Crushed stone is more expensive but offers better drainage and compacts more effectively. Joe and Jake, experienced hardscaping pros, suggest using stone sized between 1/2 inch and 3/4 inch. This size handles the heaving forces from freeze/thaw cycles well.

Avoid rounded stones like pea gravel or river rock as they don’t form strong interlocking bonds like angular stone does.

Compaction

Compacting the base material is a step that should not be skipped. Whether you use a hand tamper or a vibrating plate compactor, ensuring the soil and base material are compacted is key to preventing your wall from settling. Settling can lead to a weak wall that may eventually tip over.

Pro Tip: Compact the soil in the trench bottom before adding the crushed stone. This initial compaction step is often missed but is essential for stability.

Leveling

Leveling ensures that your wall stands straight and strong. Use a laser level and a story pole to determine the depth of the trench and ensure it is even. A level trench means an even layer of base material, which helps prevent the wall from tipping during freeze/thaw cycles.

For the first course, use a torpedo level to level each block front to back and a 4-foot or 6-foot level to keep each course even. Set the blocks with a heavy rubber or plastic mallet to get them perfectly level.

Pro Tip: Lay the first course as close to the center of the trench as possible. This ensures the wall’s weight is evenly distributed, providing a strong foundation for your large retaining wall construction.

By following these steps, you ensure a strong foundation for your large retaining wall. Next, we’ll discuss Constructing the Retaining Wall.

Constructing the Retaining Wall

Layering

Layering is crucial in large retaining wall construction. Start by laying the first course of blocks as close to the center of the trench as possible. Use a torpedo level to ensure each block is level from front to back. For accuracy, use a 4-foot or 6-foot level to keep the entire course even. This is the most important step, so take your time.

Once the first course is perfect, continue stacking the blocks. Use a heavy rubber or plastic mallet to set each block in place. Make sure each block interlocks properly with the one below it. This interlocking design helps the wall resist soil pressure.

Pro Tip: Sweep each block before stacking. Even a small pebble can throw the alignment off, causing problems later.

Backfilling

Backfilling is the process of filling the space behind the wall with material. This is important for stability and drainage.

- After laying each course of blocks, backfill with crushed stone. Use the same type of stone for backfilling as you did for the base. Crushed stone sized between 1/2 inch and 3/4 inch is ideal.

- Compact the backfill material every 6 inches using a hand tamper or a vibrating plate compactor. This ensures the material is packed tightly, providing additional support against soil pressure.

Pro Tip: Backfill a few inches at a time, compacting as you go. This prevents settling and provides a stronger wall.

Drainage

Proper drainage is essential to prevent water pressure from building up behind the wall. Groundwater is an enemy of retaining walls, especially in clay-type soils that swell when saturated.

- Install a flexible perforated drainpipe, also known as “drain tile,” at the base of the wall. This pipe will carry groundwater to each end of the wall where it can drain away.

- Cover the drainpipe with crushed stone to camouflage its appearance and improve drainage efficiency.

- Backfill the space behind the blocks with either sand or pea gravel. These materials allow water to filter through to the drainpipe.

Pro Tip: Ensure the ends of the drainpipe exit on each end of the wall for effective drainage.

Interlocking

Interlocking blocks are designed to click into place, providing additional stability. Each block has a locking flange on the bottom edge, guiding it to sit slightly behind the lower block. This creates a slight backward slope, making the wall more resistant to soil pressure.

- As you stack each course, ensure the blocks interlock properly.

- The slight backward slope (1 inch for every 1-foot of height) helps the wall lean into the soil, making it less likely to be pushed outward.

Pro Tip: Use interlocking blocks to make the construction process easier and the wall more stable.

By following these steps—layering, backfilling, ensuring proper drainage, and using interlocking blocks—you’ll build a strong, long-lasting retaining wall. Next, we’ll discuss Ensuring Stability and Durability in Large Retaining Walls.

Ensuring Stability and Durability in Large Retaining Walls

When it comes to large retaining wall construction, ensuring stability and durability is crucial. Here’s how to achieve that:

Engineering

For walls taller than 4 feet, professional engineering is a must. An engineer will design the wall to withstand the pressure of the soil, especially when it’s wet. For instance, a 4-foot tall and 15-foot long retaining wall might need to support up to 20 tons of soil pressure. Miscalculations can lead to bulging or even collapse.

Case Study: In Houston, engineers used Redi-Rock blocks to double the capacity of a detention basin while dealing with tight footprints and poor soil conditions. The new gravity wall reached a depth of 19 feet, showcasing the importance of engineering in large projects.

Geogrid

Geogrid is a soil reinforcement system that adds strength to the retaining wall. It’s a mesh-like material placed between layers of backfill to stabilize the soil.

Key Points:

– Geogrid helps distribute the load and increases the wall’s overall stability.

– The engineer will specify the type and placement of geogrid based on the wall’s height and soil conditions.

Soil Reinforcement

Soil reinforcement involves various techniques to strengthen the soil behind the wall. This is essential for walls over 4 feet tall.

Methods:

– Compaction: Compacting the soil in layers helps to eliminate air gaps, making the soil denser and more stable.

– Backfilling with Stone: Angular stone is recommended for backfilling as it provides better drainage and compaction.

Pro Tip: Versa-Lok recommends compacting the angular stone as you backfill, but always check the installation instructions for your specific block type.

Real-World Examples

- John C. Tune Airport: The design team used over 800 XL Hollow-Core Retaining blocks to reach a maximum height of 25.5 feet, overcoming unstable fill material.

- UK Highway Projects: Redi-Rock gravity walls saved £16 million and avoided land acquisition while meeting varied demands.

By incorporating professional engineering, geogrid, and soil reinforcement, you can ensure that your large retaining wall is both stable and durable.

Next, we’ll discuss Finishing Touches and Aesthetics.

Finishing Touches and Aesthetics

Capstones

Capstones are the crown jewels of your retaining wall. They not only provide a polished look but also add stability. Secure the capstones with a specialty landscape block adhesive, which remains flexible over time. Ensure the blocks are dry before applying the adhesive. For a professional finish, overhang the capstones by about 1 to 1-1/2 inches. Joe and Jake from Blakeborough Hardscapes recommend using a scrap 2×4 as a guide for consistent alignment.

Textures

Textures can transform a plain retaining wall into a stunning feature. Split blocks give a rough, natural finish that blends well with the landscape. If smooth cuts are needed, use a gas-powered cutoff saw. This saw can cut with or without water. While water eliminates dust, it creates a messy slurry that can stain surfaces like driveways. Always consider the surrounding environment when choosing your cutting method.

Alignment

Proper alignment is crucial for both aesthetics and stability. Stagger the overlaps and keep the butt joints between blocks as tight as possible. Large gaps can allow water and sediment to seep through, compromising the wall’s integrity. Use a soapstone pencil for marking cuts, as it washes off in the rain, unlike grease pencils or markers, which can leave permanent marks.

Real-World Examples

- George Hardscaping Projects: Our team has transformed numerous landscapes with well-aligned, beautifully textured retaining walls. One of our standout projects involved using split blocks to create a rustic look that perfectly matched the client’s outdoor decor.

By paying attention to these finishing touches, you ensure that your large retaining wall is not only functional but also a visually appealing feature in your landscape.

Next, we’ll dive into the Step-by-Step Process for constructing large retaining walls.

Large Retaining Wall Construction: Step-by-Step Process

Building a large retaining wall is a detailed process that requires careful planning and execution. Here’s a simple step-by-step guide to help you understand the essentials:

1. Excavation

Excavation is the first step in constructing a retaining wall. You need to dig a trench where the wall will sit. The trench should be wide and deep enough to accommodate the base material and at least one full course of blocks.

Pro Tip: Make the trench wide enough to leave at least 8 inches of space behind the wall for backfilling. Use a laser level to ensure the trench is even—this will prevent the wall from tipping.

2. Base

A solid base is crucial for the stability of your retaining wall. Use crushed stone rather than naturally occurring gravel. Crushed stone provides better drainage and compacts well. Place 6 to 8 inches of crushed stone in the trench and compact it thoroughly with a hand tamper or plate compactor.

Expert Insight: Crushed stone sized between 1/2 inch and 3/4 inch is ideal, especially in areas prone to freeze/thaw cycles.

3. Layering

Start laying the first course of blocks on the compacted base. Use a torpedo level to ensure each block is level front to back and a 4-foot or 6-foot level to keep the course even. This first layer sets the stage for the entire wall, so take your time to get it right.

Tip: Use a heavy rubber mallet to set the blocks and sweep off any debris before stacking the next layer.

4. Backfilling

Once you have a couple of courses laid, start backfilling behind the wall with crushed stone. This helps with drainage and adds stability. Continue laying courses and backfilling until the wall reaches the desired height.

Pro Tip: If your wall runs up a hill, step up the base after every two courses to maintain stability.

5. Capstones

Finally, add capstones to give your retaining wall a finished look. These are the top layer of blocks that cap off the wall. Make sure they are level and secure them with a suitable adhesive for added stability.

Case Study: In one of our projects, we used capstones with a textured finish to match the rustic look of the client’s property, adding both functionality and aesthetic appeal.

By following these steps, you can ensure your large retaining wall is both durable and visually appealing.

Next, we’ll answer some frequently asked questions about large retaining wall construction.

Frequently Asked Questions about Large Retaining Wall Construction

How thick should a 6 foot retaining wall be?

For a 6-foot retaining wall, the thickness is crucial for stability. Generally, the base should be about one-third the height of the wall. That means a 6-foot wall should have a base that’s 2 feet thick. This ensures the wall can handle the pressure from the soil behind it, especially when it’s wet.

What is the maximum height for a retaining wall block?

Retaining wall blocks come in various sizes, but for large projects, blocks like those from MagnumStone can be particularly effective. According to industry standards, these large retaining wall blocks can be used for walls up to 6 feet high without additional engineering. For walls above 6 feet, you’ll likely need a professional engineer to ensure safety and stability.

What are the large retaining wall blocks called?

Large retaining wall blocks are often referred to as “big blocks” or “precast concrete blocks.” Brands like MagnumStone offer hollow core blocks that are lighter and easier to work with, without sacrificing strength. These blocks cover about 8 square feet each, making them efficient for large-scale projects.

For more detailed guidance, check out our step-by-step installation guides and case studies to see how these blocks perform in real-world applications.

Conclusion

In conclusion, constructing a large retaining wall is a significant project that requires careful planning, the right materials, and precise execution. The longevity and maintenance of your retaining wall are crucial aspects to consider, and we at George Hardscaping are here to ensure your project stands the test of time.

Longevity

A well-built retaining wall can last for decades, but its longevity depends on several factors:

- Quality of Materials: Using durable materials like concrete, stone, and engineered blocks ensures the wall can withstand harsh weather conditions and immense pressure. For instance, MagnumStone’s hollow core blocks use 40% less concrete but maintain high strength, making them an excellent choice for durability.

- Proper Drainage: Adequate drainage prevents water buildup behind the wall, which can cause pressure and lead to failure. Crushed stone is preferred for the base and backfilling because of its superior drainage properties.

- Solid Foundation: A compacted, level base is essential. As our experts suggest, using a laser level and a story pole can help achieve a perfectly level trench, reducing the risk of settling.

Maintenance

Maintaining your retaining wall involves regular inspections and minor upkeep to ensure it remains in top condition:

- Inspect Annually: Check for signs of wear, such as cracks or bulges. Addressing small issues early can prevent major repairs later.

- Clean Drainage Channels: Ensure that drainage channels are clear of debris to prevent water accumulation.

- Reinforce as Needed: Over time, some walls may require additional reinforcement, especially if they are exposed to severe weather conditions or heavy loads.

George Hardscaping

At George Hardscaping, we pride ourselves on delivering customized, high-quality retaining wall solutions. Our team of experienced professionals is dedicated to ensuring your landscape retaining walls not only look great but also provide the necessary structural support and longevity.

Why Choose Us?

- Expertise: With years of experience, our team has the knowledge and skills to handle any retaining wall project, no matter the size.

- Quality Materials: We use only the best materials to ensure your wall stands the test of time.

- Customer Satisfaction: We work closely with you from the initial design to the final installation, ensuring your vision is brought to life.

Ready to get started? Contact us today for a consultation or to request an estimate. Visit our Landscape Retaining Walls page for more information.

By following these guidelines and working with a trusted partner like George Hardscaping, you can ensure your large retaining wall construction project is a lasting success.